INNOVATEST Rockwell hardness testers are designed for both standard and superficial Rockwell testing methods. These testers follow the procedures outlined in ISO 6508 and ASTM E18, the most widely used standards for measuring material hardness globally.

Manual, semi-automatic and automatic Rockwell hardness tester methods are applied to a broad range of metals and, in some cases, plastics. The method works by measuring the depth of a permanent indentation created by a defined indenter under a specific load.

Depending on the material and application, different Rockwell scales may be used, such as Rockwell HRC for harder steels, HRB for softer metals like brass, and superficial scales for thin materials or coatings.

With minimal sample preparation required, the Rockwell test remains one of the fastest and most user-friendly hardness testing methods used across diverse industries. The main advantages of using a hardness tester with the Rockwell method are:

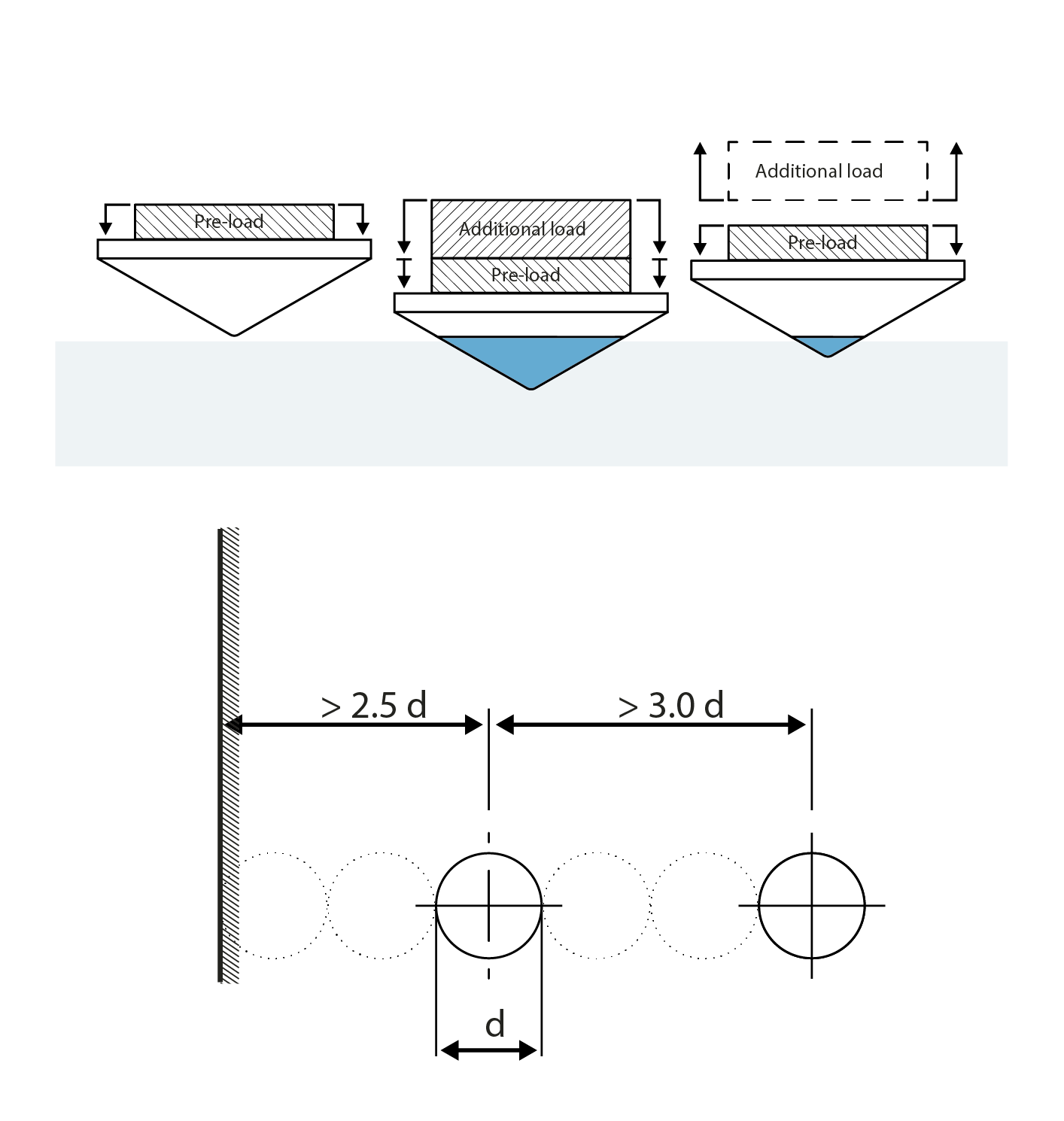

First, a minor load (preload) is applied to establish a zero or reference point. Then, a major load is added to reach the full test force and is held for a set dwell time to account for elastic recovery in the material. Once the major load is removed, the minor load remains in place, and the depth difference from the original reference point is used to calculate the Rockwell hardness value.

INNOVATEST offers various dedicated Rockwell hardness testers that are closed loop, load cell-based machines. Our instruments are developed, designed and endurance tested at our R&D facilities, and offer our customers the choice between basic manual testing or fully automatic Rockwell testing

All instruments are equipped with user-friendly, advanced IMPRESSIONS software, which allows for ease of use while accommodating complex applications and workflows. In addition, all critical internal electronic components are manufactured by INNOVATEST, allowing for a high level of manufacturing quality control and ensuring a reliable hardness testing instrument for many years, backed by our extended warranty options. View all Rockwell models here.

By understanding your testing needs and setup, we’ll recommend the right Rockwell hardness tester with the hardware, software, and configuration that fits your application. Whether you need a standard model or a customized solution, our team is here to help at any stage of your search.

To use a Rockwell hardness tester, apply a minor load (typically 10 kgf) to seat the indenter, followed by a major load. Remove after holding the major load for a set time. The depth of indentation is measured to calculate the Rockwell Hardness Number (HR).

Rockwell C represents a harder material than Rockwell B. The C scale (HRC) is used for harder steels, while the B scale (HRB) is used for softer metals like brass or aluminium alloys.

Rockwell hardness is tested by applying a two-stage load to an indenter on the test surface: first a minor load, then a major load. The depth difference after removing the major load is used to determine the Rockwell hardness value.

There is no universal “ideal” Rockwell hardness. Ideal values depend on application. For example, knife blades range from 55–62 HRC, structural steel around 20–30 HRC, and brass fittings around 60–80 HRB.