According to the Automated Imaging Association (AIA), machine vision encompasses all industrial and non-industrial applications in which a combination of hardware and software provides operational guidance to devices in the execution of their functions based on the capture and processing of images.

At INNOVATEST, we use machine vision to build high-quality automated imaging systems that solve complex hardness testing tasks reliably and consistently.

Though industrial computer vision uses many of the same algorithms and approaches as academic/educational and governmental/military applications of computer vision, constraints are different. INNOVATEST machine vision is an integrated part of our hardness testing automation and combines optical systems with refined algorithms for indent measurement, work stage overview and workpiece visualization.

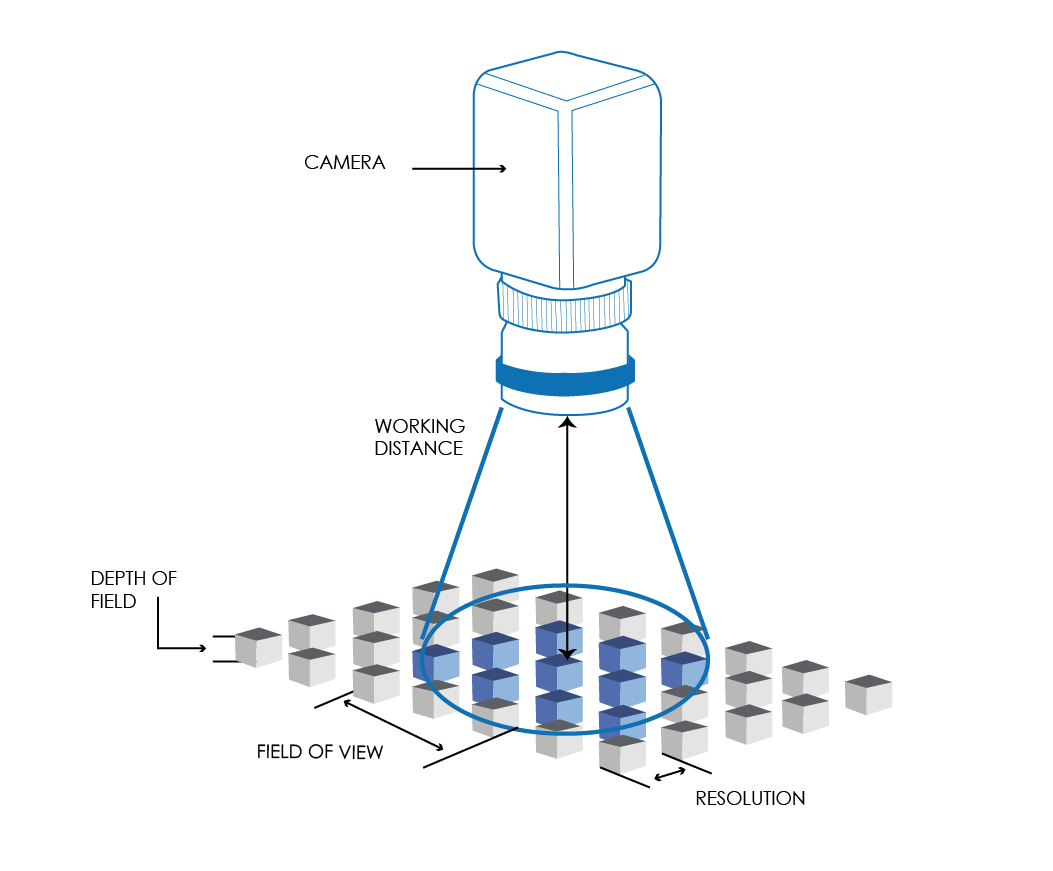

We use cameras with high-speed frame rates and a variety of resolutions up to 18 megapixels, automatic indent and workspace zooming systems. Ultra Bright ringlight technology, LED panels and sophisticated optical filtering methods to refine and ultimately provide the best possible hardness measurement.

While most of the INNOVATEST hardness testing machines make use of sophisticated ultra-high resolution industrial camera systems, with LED ring light or LED panel lights, our more basic models like the FALCON 400 and 450 make use of a proven concept of a metallurgical microscope with a LED based Köhler illumination.

Köhler illumination is a method of specimen illumination used for transmitted and reflected light (trans- and epi-illuminated) optical microscopy. It generates an even illumination of the sample and ensures that an image of the illumination source – for example in the early days a halogen lamp and nowadays LED lamp filament, is not visible in the resulting image.

Köhler illumination is the predominant technique for sample illumination in modern scientific light microscopy. It requires additional optical elements which are more expensive and may not be present in more basic light microscopes.

Talk to our experts to understand the full scope of our hardness testers and how our cutting-edge automated imaging systems can help optimize your production and ensure quality and consistency.

Imaging systems in hardness testing are built-in digital camera systems used to capture and analyze indentations. These systems are commonly found in Vickers, Knoop, and Brinell hardness testers, where precise measurement of the indent is critical.

Integrated imaging allows for automatic indent detection, measurement, and evaluation without manual input. This improves accuracy, repeatability, and testing speed. Many modern hardness testers use integrated imaging systems with features like auto-focus, image enhancement, and real-time indent visualization, helping laboratories and production facilities reduce operator error and ensure consistent results.

An example of an imaging system in hardness testing is a digital optical measurement system integrated into a Vickers or Brinell tester. One widely used solution is the INNOVATEST IMPRESSIONS™ software, which uses a high-resolution camera and intelligent software to automatically detect and measure indentation size.

It supports features such as auto-indent centering, digital zoom, edge detection, and real-time image capture, streamlining the hardness testing process. This type of integrated imaging system is ideal for automated testing workflows and advanced material analysis, especially where precision and speed are critical.