The Knoop hardness tester is designed for microhardness testing, which refers to evaluating very thin materials, coatings, or brittle samples where only a minimal indentation is acceptable. This hardness testing method uses a low test force and a uniquely shaped diamond indenter to deliver precise hardness measurements at the microscale.

INNOVATEST Knoop hardness testers, manufactured in the Netherlands, are engineered for accuracy and reliability. We offer one of the largest selections of microhardness testers, backed by expert service and support.

While both Knoop and Vickers tests fall under microhardness testing, they differ in indentation geometry and measurement sensitivity:

Knoop indentations are elongated and asymmetrical, which allows for more precise hardness mapping over very small distances. Meanwhile, Vickers indentations are square and symmetrical, offering more stable readings at slightly higher forces.

Knoop microhardness testers are generally preferred when dealing with thin coatings or delicate materials. They’re especially suitable for test forces below 200 gf, where variations in measurement are more likely.

The Knoop hardness test applies a precision diamond indenter with a long and short diagonal, creating an elongated indentation. The test force typically ranges from 10 gf to 1000 gf, though special cases may use up to 2 or 5 kgf.

Knoop is not commonly used to measure bulk hardness, except in specific cases like 500 gf, where ASTM standards provide conversions to other scales. Larger test forces may be used, but variations can happen depending on the material and setup.

The Knoop method is especially valuable for testing the variations of hardness over small features, cross-sections, or surface gradients.

Proper sample preparation is critical for Knoop testing. Surface imperfections such as corrosion, scratches, or deformation can significantly affect results, especially at lower test forces. Removing all surface damage ensures accurate and repeatable measurements.

What is the formula for calculating Knoop hardness number (KHN)? The HK is calculated using the following formula:

![]()

INNOVATEST offers various Knoop hardness testers that are closed loop, load cell-based machines. Our instruments are developed, designed and endurance tested at our R&D facilities, and offer our customers the choice between basic manual testing or fully automatic Knoop testing.

All instruments are equipped with user-friendly, advanced IMPRESSIONS software which allows for ease of use while accommodating complex applications and workflows. In addition, all critical internal electronic components are manufactured by INNOVATEST, allowing for a high level of manufacturing quality control, and ensuring a reliable hardness testing instrument for many years, backed by our extended warranty options.

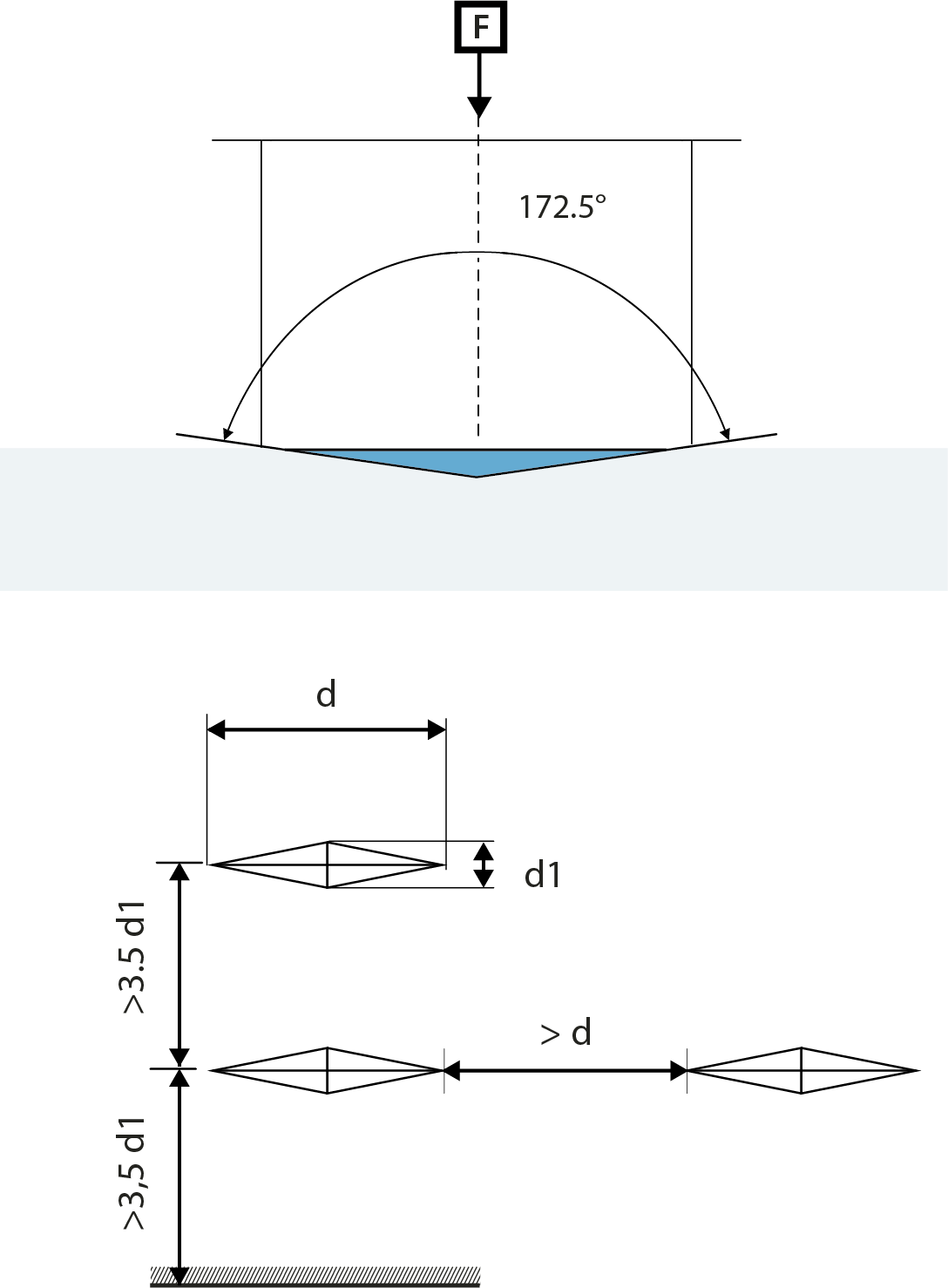

Diagrams illustrating the Knoop test method and

suitable indent spacing based on ISO and ASTM standards

The Knoop hardness test is used for measuring very thin materials, coatings, or small parts. It’s especially useful in microhardness testing for ceramics, composites, and metallographic samples.

Both are microhardness tests, but Knoop uses an elongated diamond-shaped indenter that produces a shallow indentation, ideal for thin samples. Vickers uses a symmetrical diamond pyramid and is better for isotropic materials.

Knoop hardness values (HK) can range from below 100 for soft metals to over 2000 HK for hard ceramics and coatings.

HK stands for Knoop Hardness Number, indicating a material’s resistance to indentation under very light loads, typically measured in microhardness testing.