The Vickers hardness tester uses a widely trusted method for measuring hardness across a broad range of materials. Developed in 1924 by Smith and Sandland at Vickers Ltd, the micro Vickers hardness tester method was introduced as a more versatile alternative to Brinell testing.

One of the key advantages of the Vickers method is its consistency: the calculations are independent of the indenter size, and a single diamond indenter can be used for both hard and soft materials. This makes the use of Vickers hardness tester machines or methods suitable for a wide variety of applications.

Like other hardness tests, the Vickers method measures a material’s resistance to plastic deformation. It uses a diamond-shaped indenter in the form of a square-based pyramid, which is pressed into the surface of the test material under a controlled load.

An indentation will be left behind after the process, and this is measured diagonally. The result is called the Vickers Pyramid Number (HV), also known as Diamond Pyramid Hardness (DPH). Because of its precision, this test is suitable for assessing both micro and macro hardness.

To guarantee reliable and precise results, the micro Vickers hardness test follows these essential principles:

Vickers hardness values are reported using a standardized format such as xxxHVyy, for example 440Hv30, or xxxHVyy/zz, where:

If the dwell time differs from the standard (10 to 15 seconds), it is included as well:

440HV30/20 indicates a 20-second load time.

Vickers hardness testers are used across industries for:

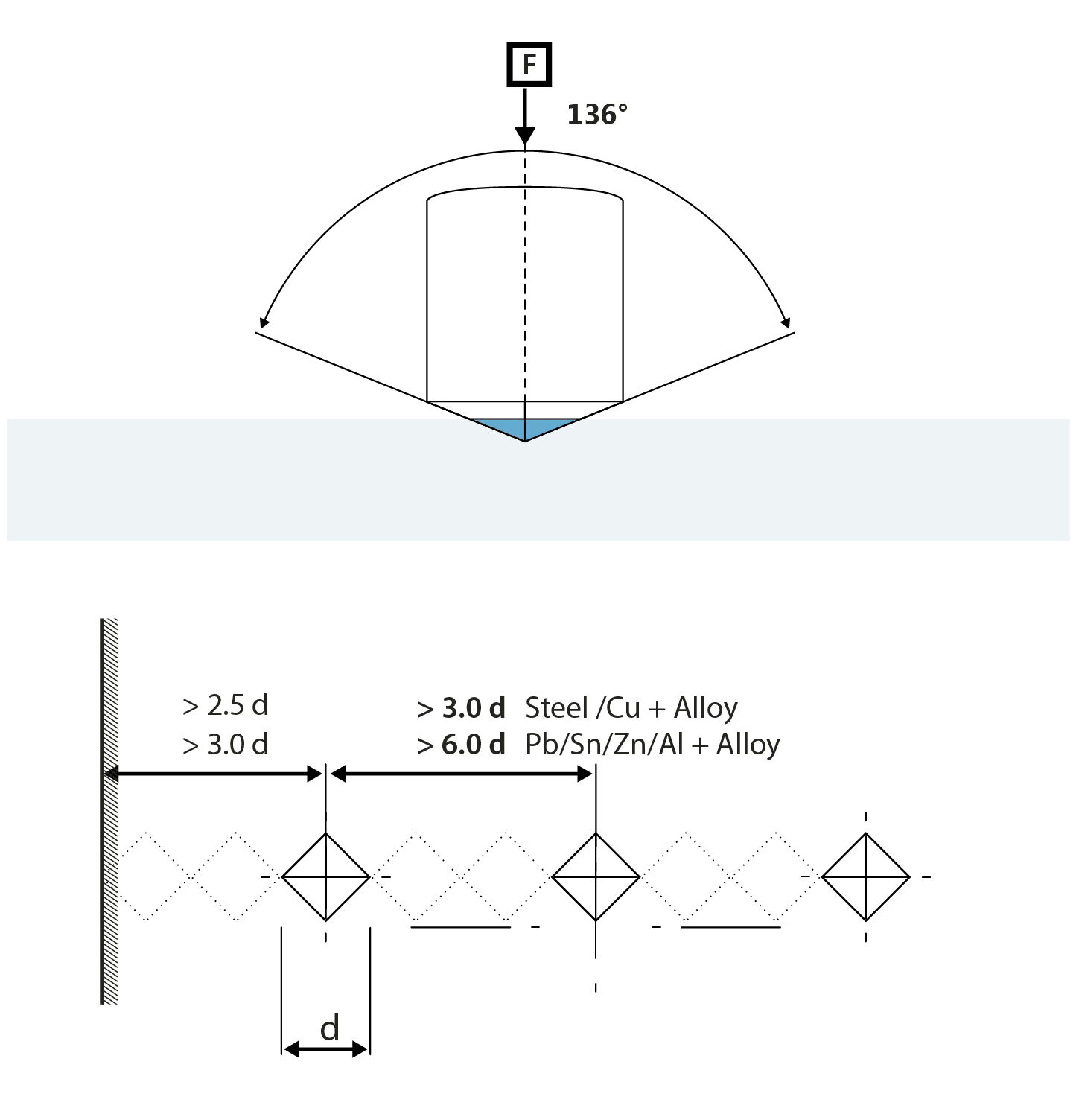

The method is preferred for its ability to provide tensile strength correlations, and insights into wear resistance and ductility. While Vickers results are generally independent of the applied test force (within 500 gf to 50 kgf), care must be taken to space indentations at least three diameters apart to avoid work-hardened interference.

Common fields of use include:

INNOVATEST offers various Vickers hardness testers that are closed loop, load cell-based machines. Our instruments are developed, designed and endurance tested at our R&D facilities, and offer our customers the choice between basic manual testing or fully automatic Vickers testing.

All instruments are equipped with user-friendly, advanced IMPRESSIONS software, which allows for ease of use while accommodating complex applications and workflows. In addition, all critical internal electronic components are manufactured by INNOVATEST, allowing for a high level of manufacturing quality control and ensuring a reliable hardness testing instrument for many years, backed by our extended warranty options.

Diagrams illustrating the Vickers test method and

suitable indent spacing based on ISO and ASTM standards

To use a Vickers tester, a diamond pyramid-shaped indenter is pressed into the material using a precise load. After the load is removed, the diagonals of the indentation are measured to calculate the Vickers Hardness Number (VHN).

Vickers hardness is a measure of a material’s resistance to plastic deformation, calculated from the size of an indentation made by a diamond pyramid under a known load.

The Vickers test is a micro- or macro-indentation hardness test using a diamond pyramid indenter and precise loads. It is suitable for a wide range of materials, including metals and ceramics.

The Vickers test is used for evaluating surface hardness in thin materials, coatings, and precision components. It’s commonly applied in research, quality control, and metallurgical analysis.

Vickers hardness is measured by applying a load to a diamond indenter, measuring the diagonals of the resulting square-shaped indentation, and calculating the hardness value using the standard Vickers formula.